Kaizen Events A Complete Guide To Planning & Holding A… Tulip

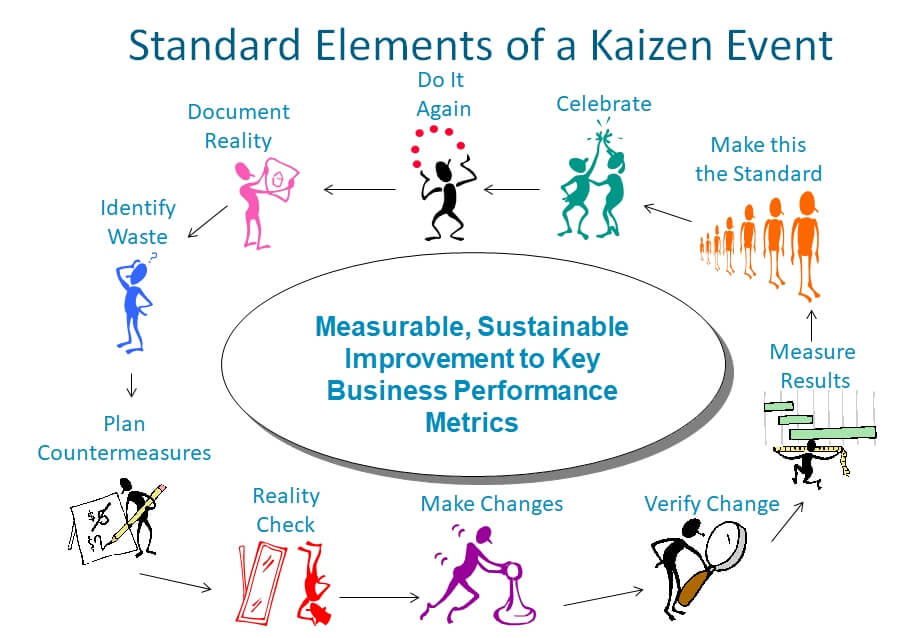

Kaizen event is a short-term initiative to improve targeted areas in work processes. It does not target an entire process and it lasts for a few (3-5) days. It is a tool that improves work processes and eliminates waste. In addition, the exercise can be relevant to any area of an organization.

5S Kaizen Stock Image Image 28197211

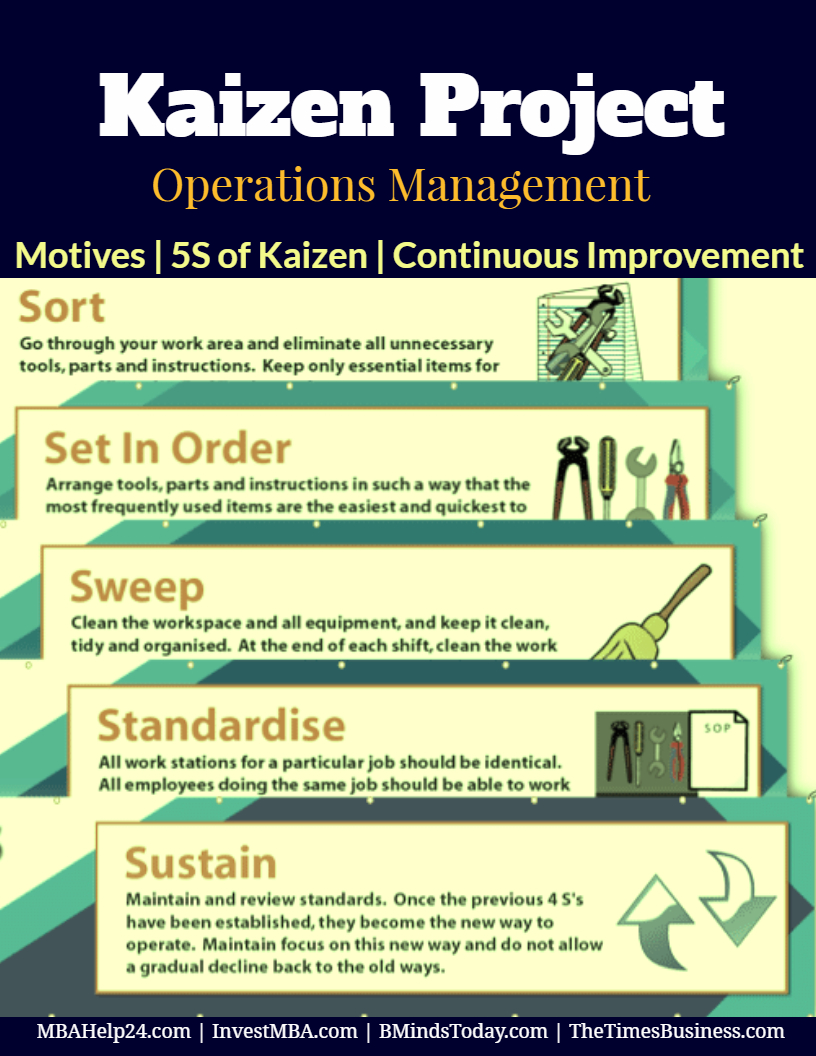

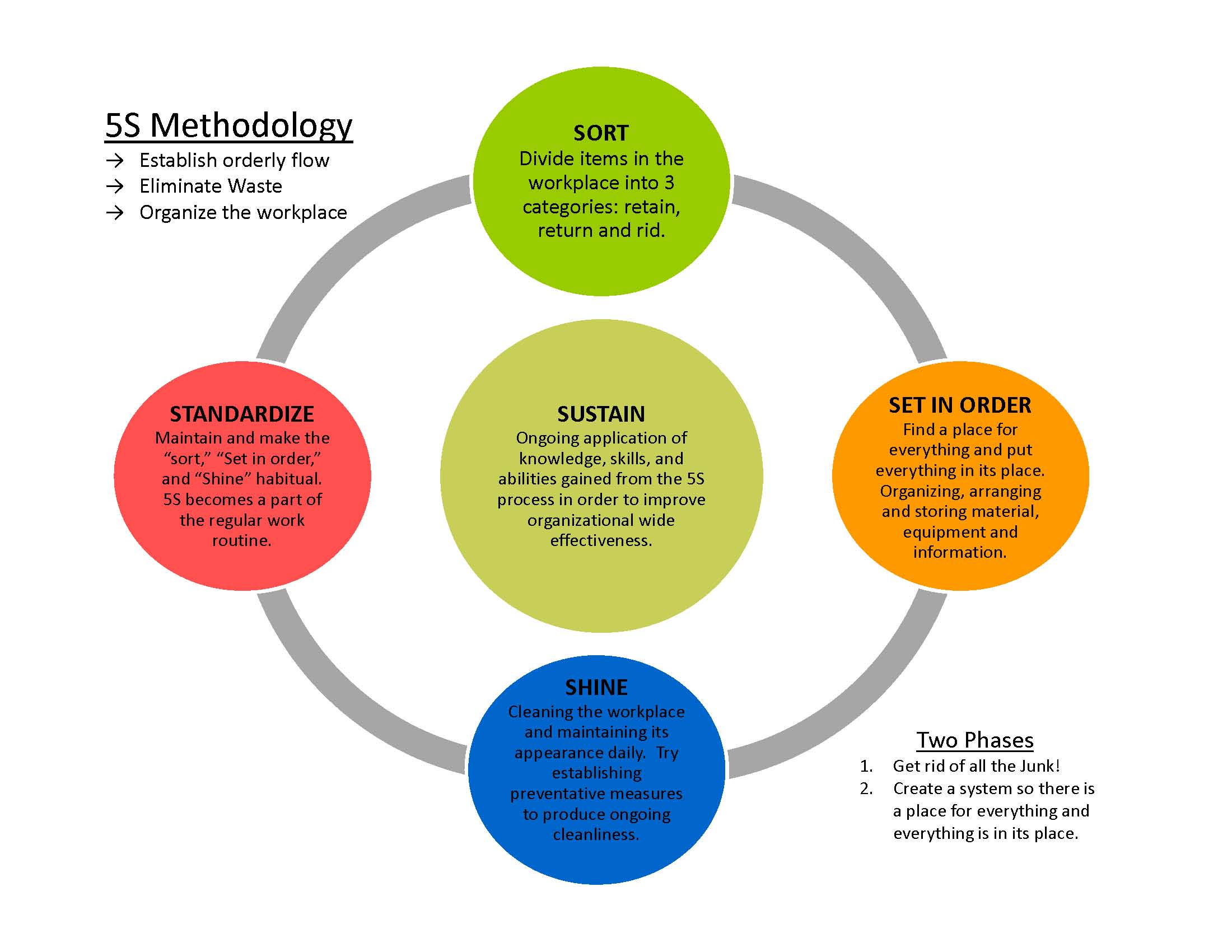

5S Kaizen TPM Kaizen Setup Reduction Kaizen (SMED) Value Stream Mapping or Flow Kaizen Supply Chain Kaizen Whatever you call them however these events all have common aims and structures and look to harness the ideas and creativity of your workforce in creating a step change improvement in a specific area of your business.

What is 5S? 5S System is explained including tips on getting a 5S program started.

According to Villanova's Lean Six Sigma Black Belt course, a five-day Kaizen Event should follow these steps. Day 1: Begin training on fundamental Lean principles. The team should perform a waste walk (identifying areas of waste in a process) and gather data. Day 2: Brainstorm ideas to improve the process.

5S Lean 5S Principles in the Workplace SafetyCulture

Oct 18, 2018 What is a Kaizen event or Kaizen blitz? Kaizen events, also known as Kaizen blitzes, are short-duration events, usually in the form of a week-long workshop, in which a facilitator guides a team in improving an area with a specific goal in mind.

Kaizen Project Benefits Five S Of Kaizen Riset

A key component of the Kaizen culture is the 5S Method, a simple yet powerful tool for process improvements. Understanding the 5S Method in a Kaizen Event. A Kaizen event, or a Kaizen improvement event, is a focused and structured workshop where cross-functional team members come together to improve an existing process rapidly.

Article Understanding the 5S's of Kaizen 6 Sigma

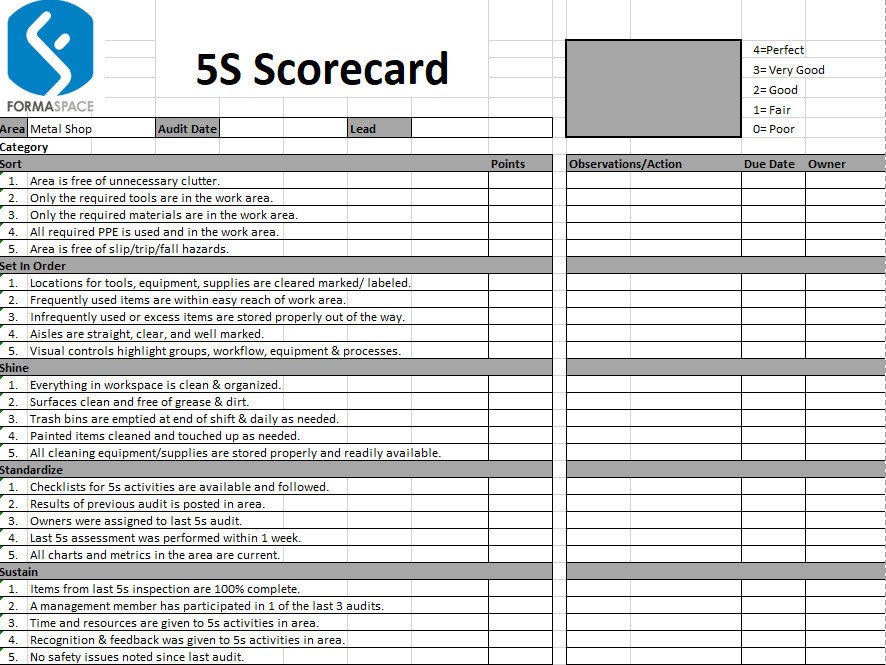

A successful 5S event is a powerfully visible and motivating demonstration of results, and planning is the key to achieving this. Proper planning is the most critical factor to being able to move rapidly through the 5S phases, to keep everyone busy and focused, and avoid people getting distracted by other demands or simply wandering off in.

The Tools of Kaizen 5S Today

What is a KAIZEN™️ Event? Focused on the organization's need for improvement, a KAIZEN™️ Event is an intensive workshop typically divided into three phases: 1. Preparation In this phase, relevant data is collected, and necessary equipment and materials are prepared.

5S Continuous Improvement Blog

A 5S kaizen event is a method to implement the 5S methodology in sections of an organization. 5S is one of the most widely adopted techniques from the LEAN toolbox. The primary objective of 5S is to create a clean, orderly environment- an environment where there is a place for everything, and everything is in its place.

Kaizen events Lean Management Program

5s | What is a 5S Event? | Kaizen Event | Lean manufacturing Articles What is a 5S Event? November 27th, 2018 5S is a popular and commonly-used tool in Lean manufacturing and is used for the optimization of workplace conditions. Often, 5S is used as a key building block within many lean continuous improvement efforts.

Certificate course Kaizen 5S technique Tickets by Biz iuris College of Professional studies

The purpose of a 5S kaizen event is to implement 5S in an area in need of cleanliness and organization. This chapter is designed to show you step by step how to conduct a 5S kaizen event. 5S implementation is always a good starting point for a newly established lean journey.

The 5S's of Kaizen Poster

5S: The Foundation for Kaizen. 5S (Sort, Set in Order, Shine, Standardize, and Sustain) often serves as a foundational element for Kaizen Events. Before diving into a complex problem-solving effort, organizations may use 5S to set the stage for a smoother and more organized Kaizen Event. Kaizen in the Digital Age

How Kaizen Can Improve Your Manufacturing Production Quality Formaspace

Kaizen events are short-term improvement projects that aim to eliminate waste and increase efficiency in a specific process or area. One of the most common and effective tools for kaizen.

5 Step Kaizen Program

A 5S Kaizen event is a focused improvement activity that involves a team of operators and other stakeholders in applying the 5S principles to a specific area, such as your packaging area. In.

5S. Kaizen management methodology. Workplace organization method that uses a list of five words

A Kaizen Event is designed to support an effective, short-term brainstorming session that focuses on a single challenge and improves an existing process. The term is loosely translated from the Japanese to "change for the good.". As with many strategies involved in Lean and Six Sigma, the governing idea behind a Kaizen Event is focus and speed.

Unleashing the Power of Kaizen A Comprehensive Guide to Implementing the 5S Method for

5S is defined as a methodology that results in a workplace that is clean, uncluttered, safe, and well organized to help reduce waste and optimize productivity. It's designed to help build a quality work environment, both physically and mentally. The 5S philosophy applies in any work area suited for visual control and lean production.

Kaizen Events How and when to use them Know Industrial Engineering

The Benefits of 5S. After your 5S focused Kaizen event, you will enjoy: More effective use of space, time, resources. Reduced waste in searching for items or finding a place to put them when they are used. Increased pride in the workplace with a sense of ownership and investment. Improved safety.